English III

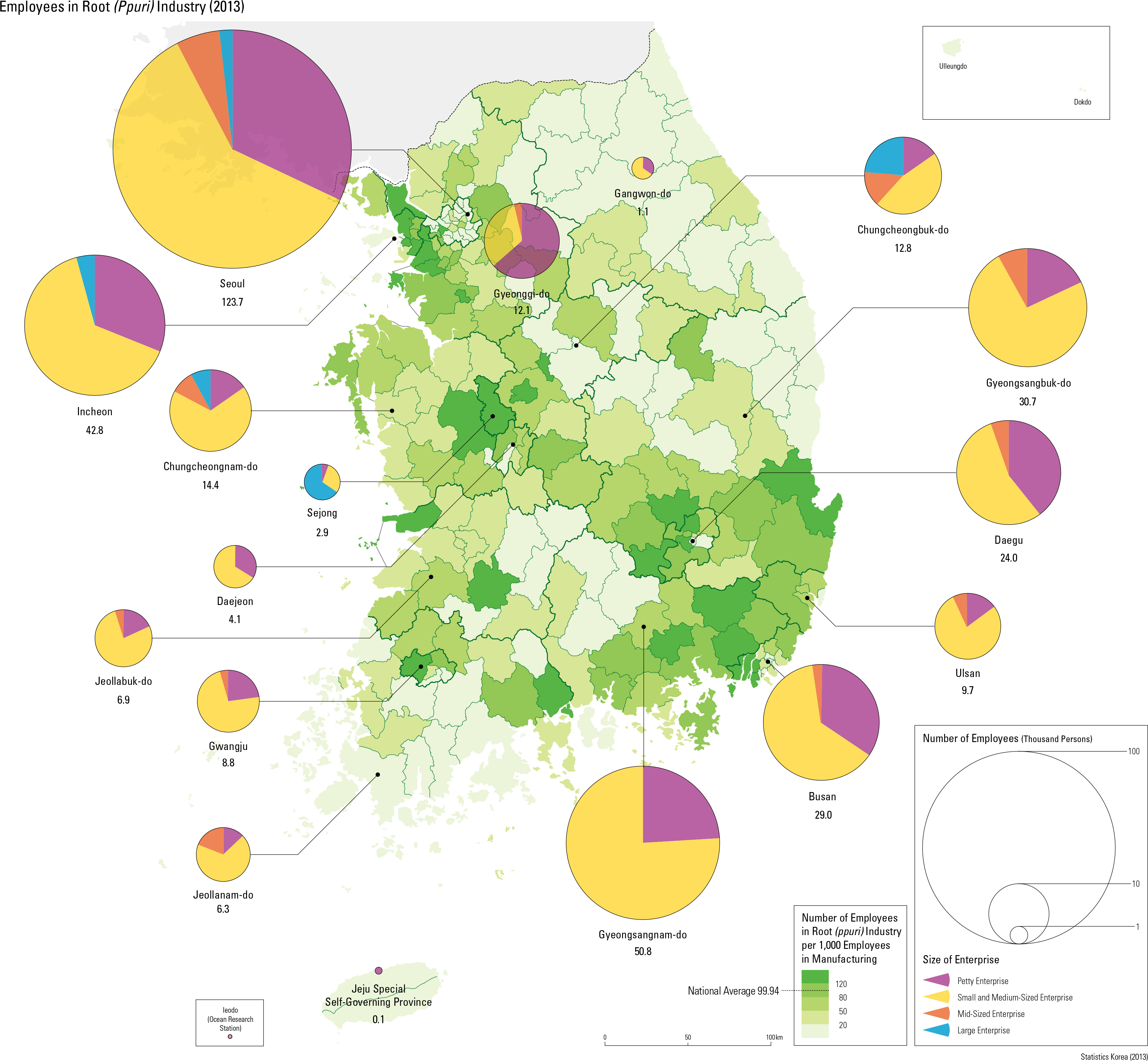

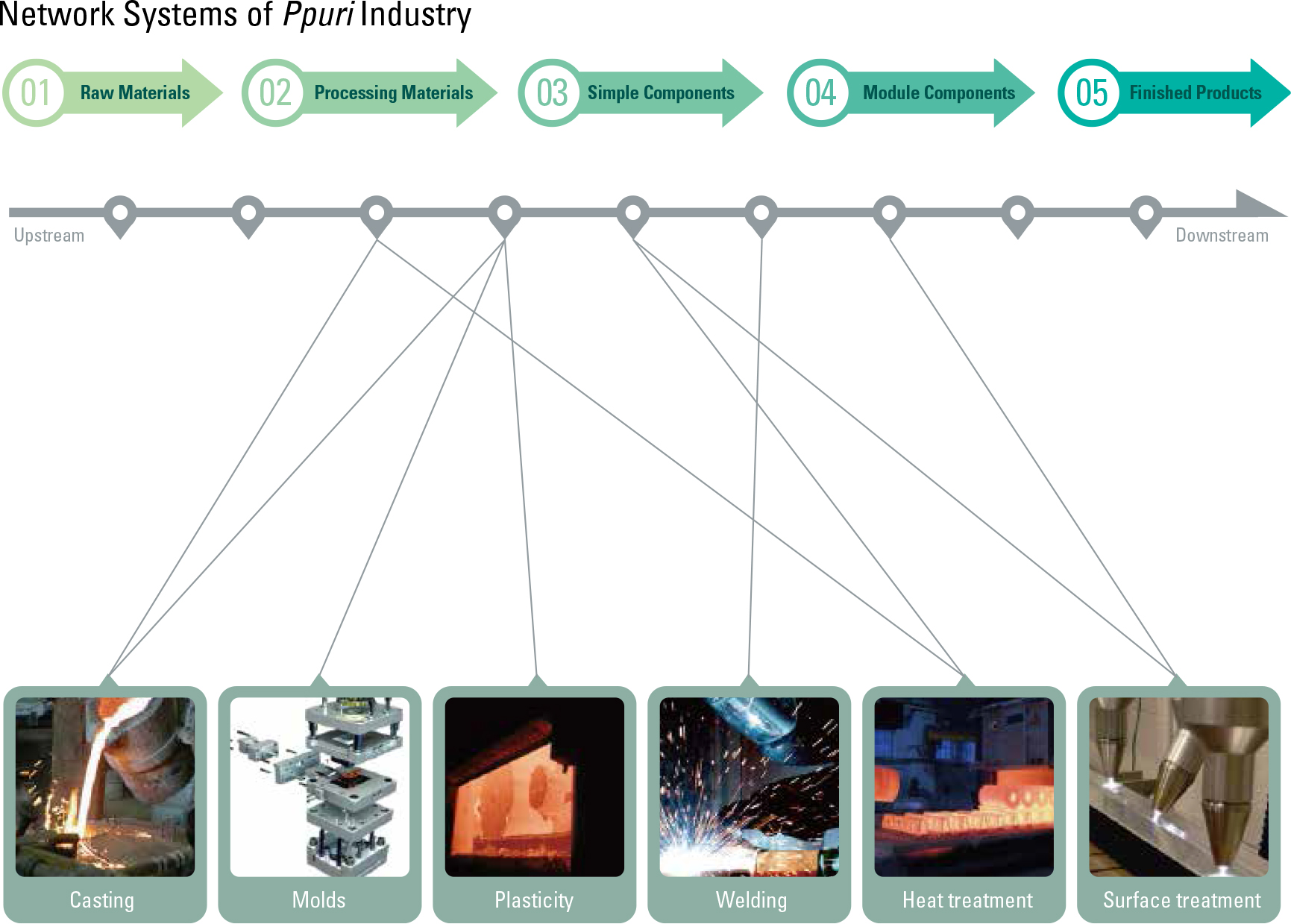

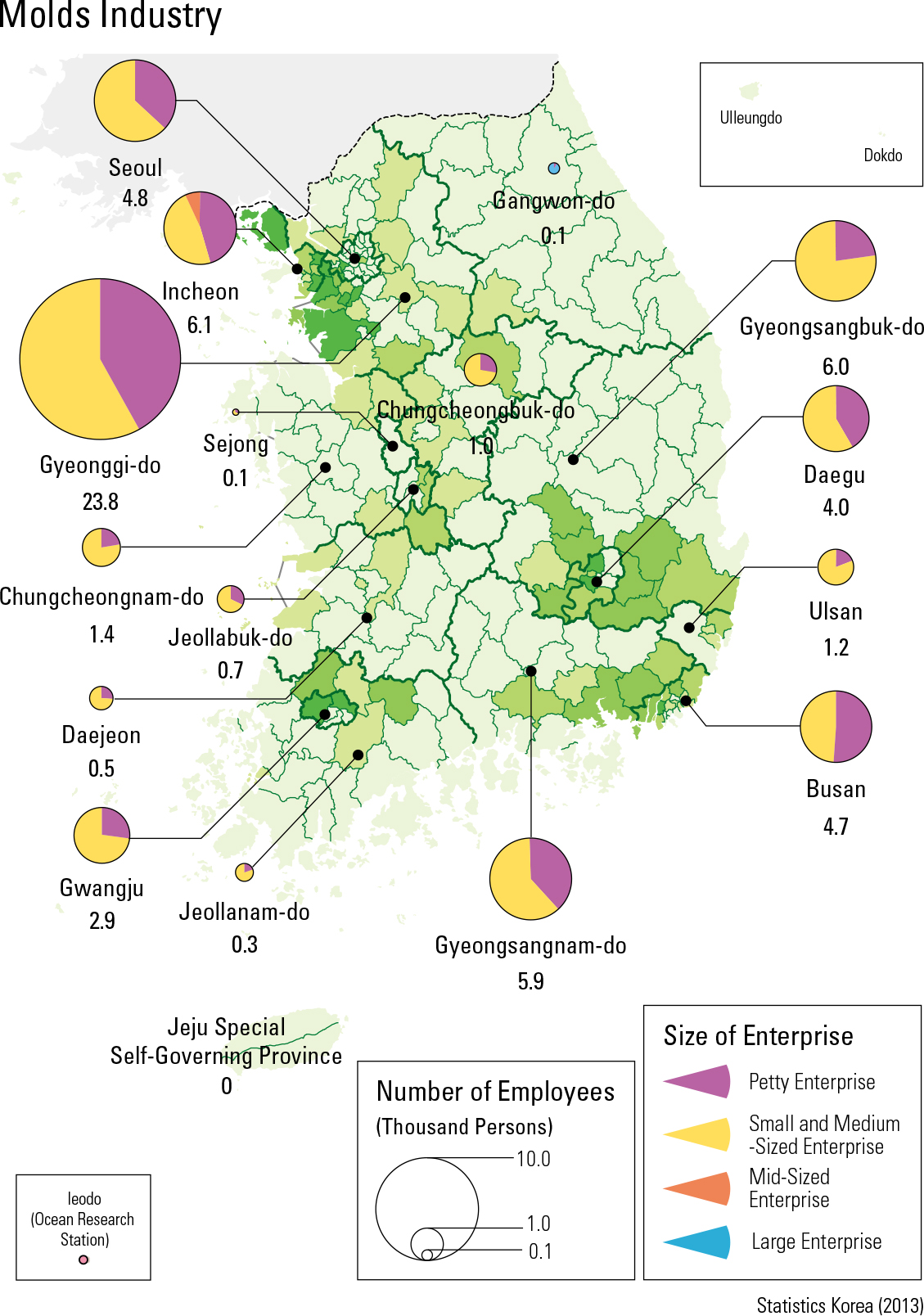

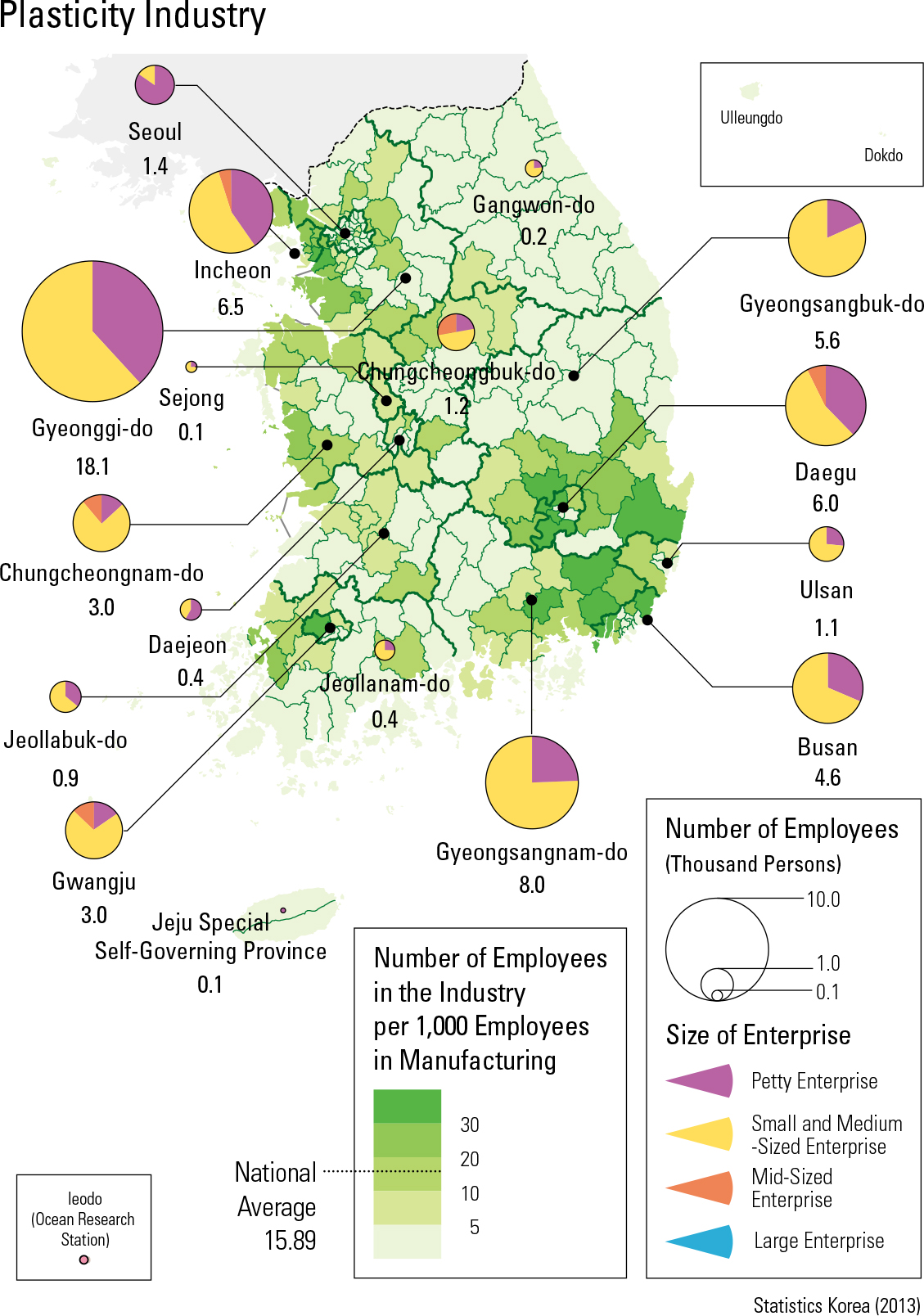

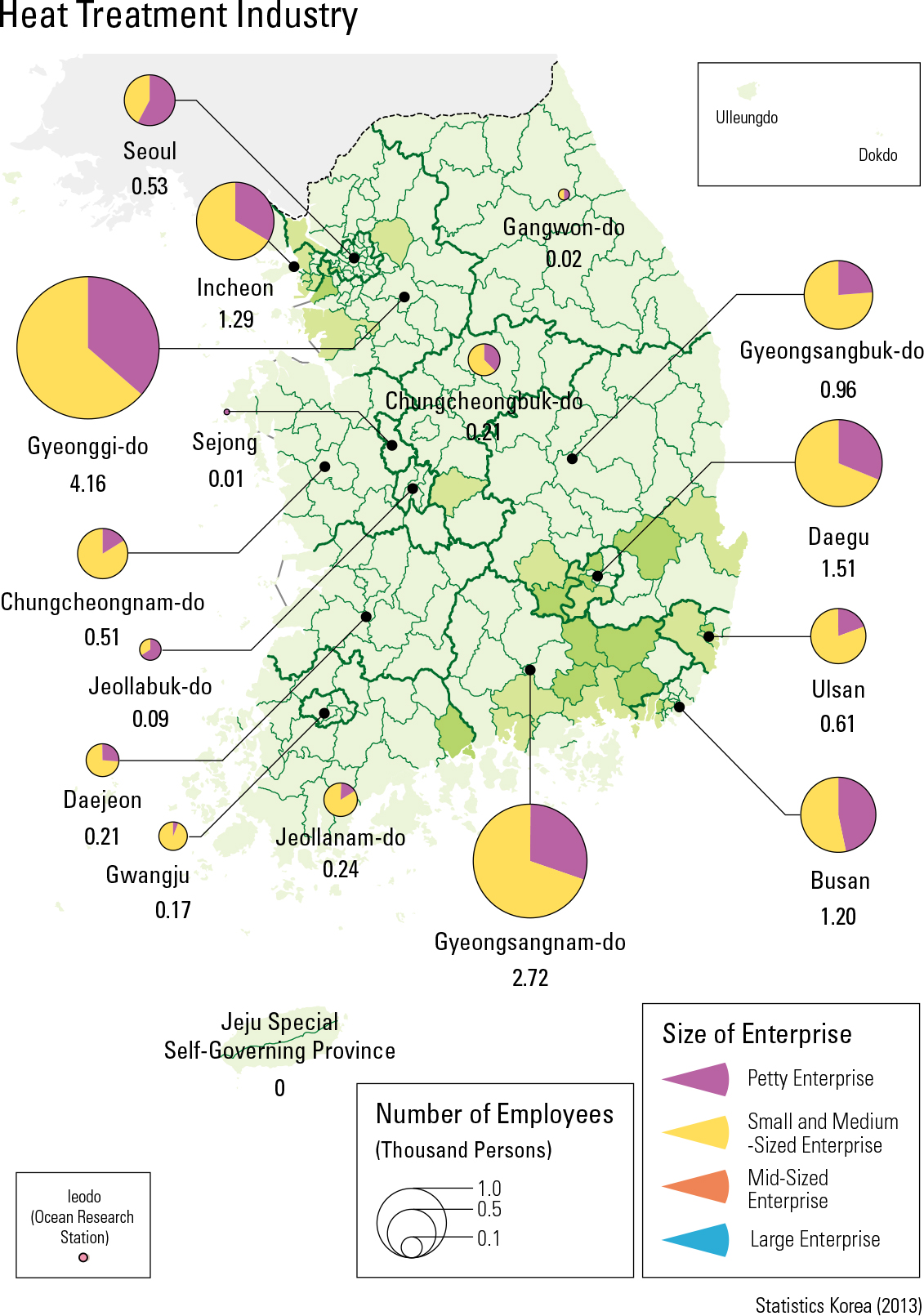

The Ppuri industry produces components from raw materials, produces final products from com- ponents, and improves the competitiveness of the quality of nal products by utilizing process tech- nologies for castings, molds, plasticity, welding, thermal processing, and surface treatment processes as a service to other manufacturing industries such as the automobile, shipbuilding, and IT industries. (Ppuri Industry Promotion Act, Article 2). The Ppuri industry is an emerging future growth engine in the Korean economy; it enhances the value of the products of the new growth engine industries under the latest inter-technology cooperation. In 2013, the Korean Ppuri industry consisted of 40,723 Ppuri enterprises and manufacturers that applied the Ppuri technology in the nishing pro- cess. It accounted for 11.0% of all manufacturing enterprises and 380,000 employees, or 10.0% of all manufacturing employees. There were 6 large enterprises, 45 mid-size enterprises, 8,244 SMEs, and 32,428 petty enterprises, representing shares of 0.01%, 0.1%, 20.2% and 79.6%, respectively, re ecting a typical small industrial structure. Gyeonggi-do has the highest regional concen- tration of Ppuri industries (34.3%), followed by Incheon (11.6%), Gyeongsangnam-do (10.7%), Busan (9.3%), Seoul (8.8%), Daegu (8.6%), and Gyeongsangbuk-do (5.2%). Of the total Ppuri in- dustries, 54.6% are distributed in the Greater Seoul Metropolitan area. The proportion of Ppuri manu- facturing employees compared to the total number of manufacturing workers is highest in Jeungpy- eong-gun (32.8%), followed by Goryeong-gun (32.1%), Ansan-si (27.3%), Seo-gu in Incheon (24.2%), Buk-gu in Daegu (22.5%), Namdong-gu in Incheon (22.3%), Sasang-gu in Busan (21.6%), Siheung-si (20.9%), and Nam-gu in Incheon (20.5%).

page_2 |