English III 2021

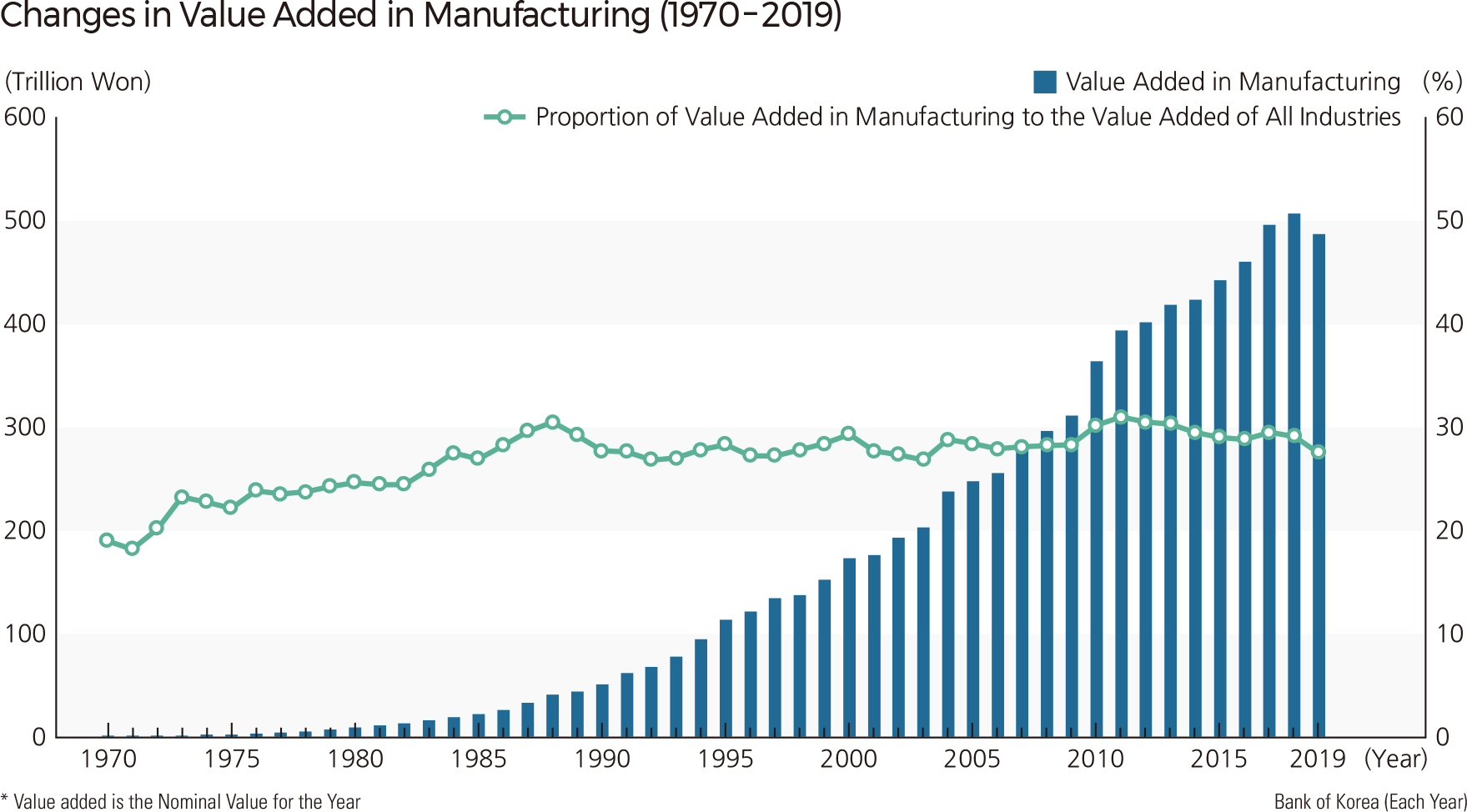

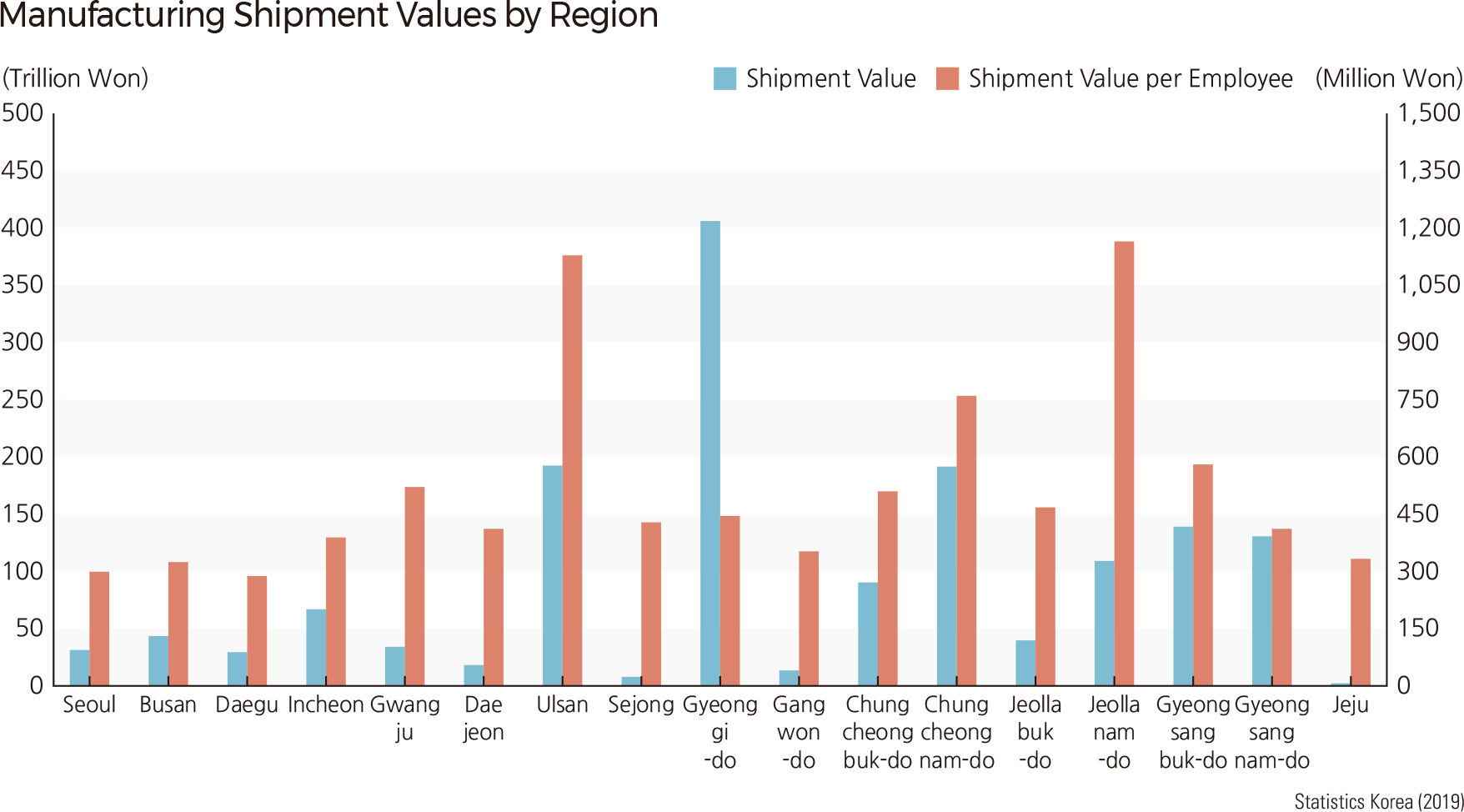

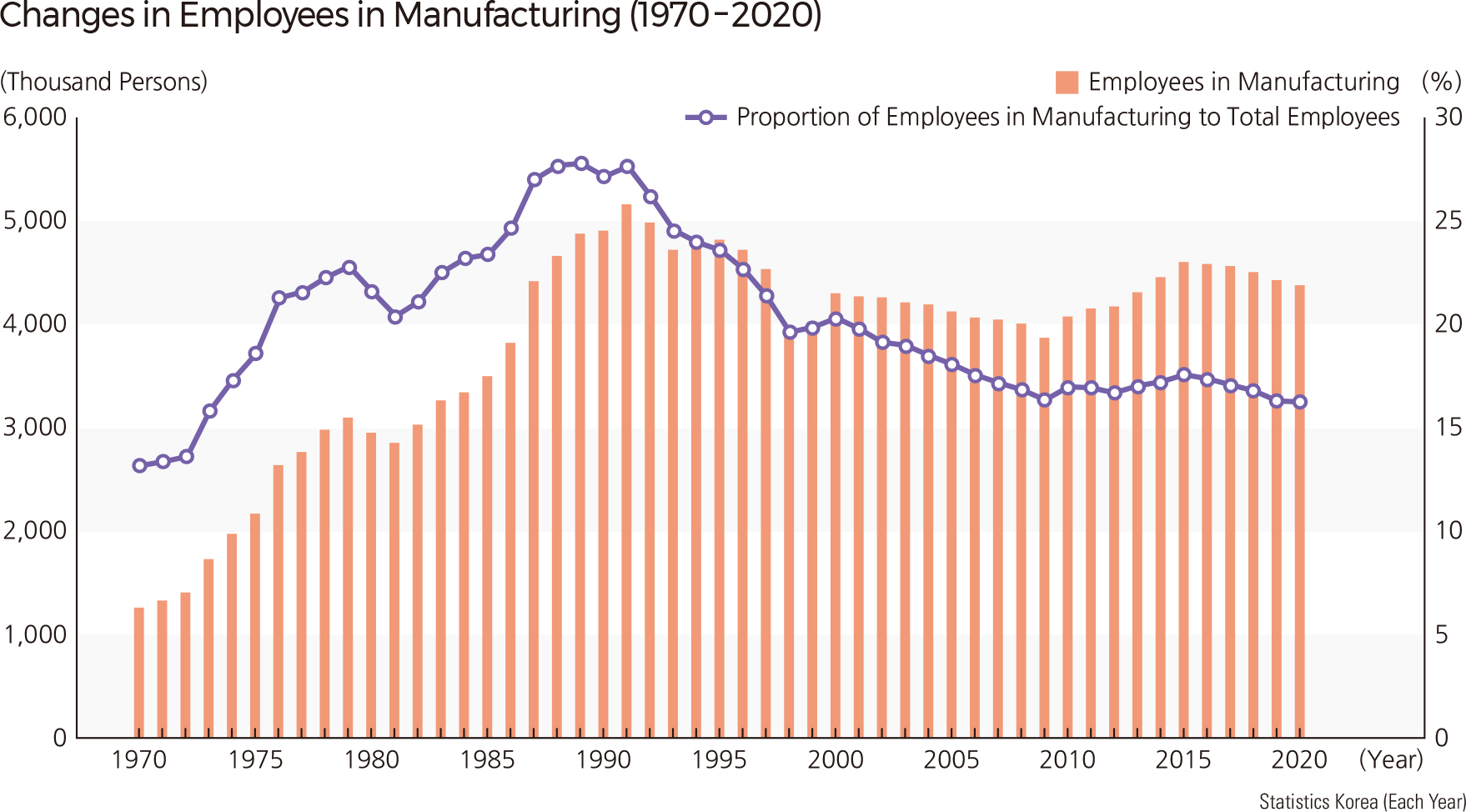

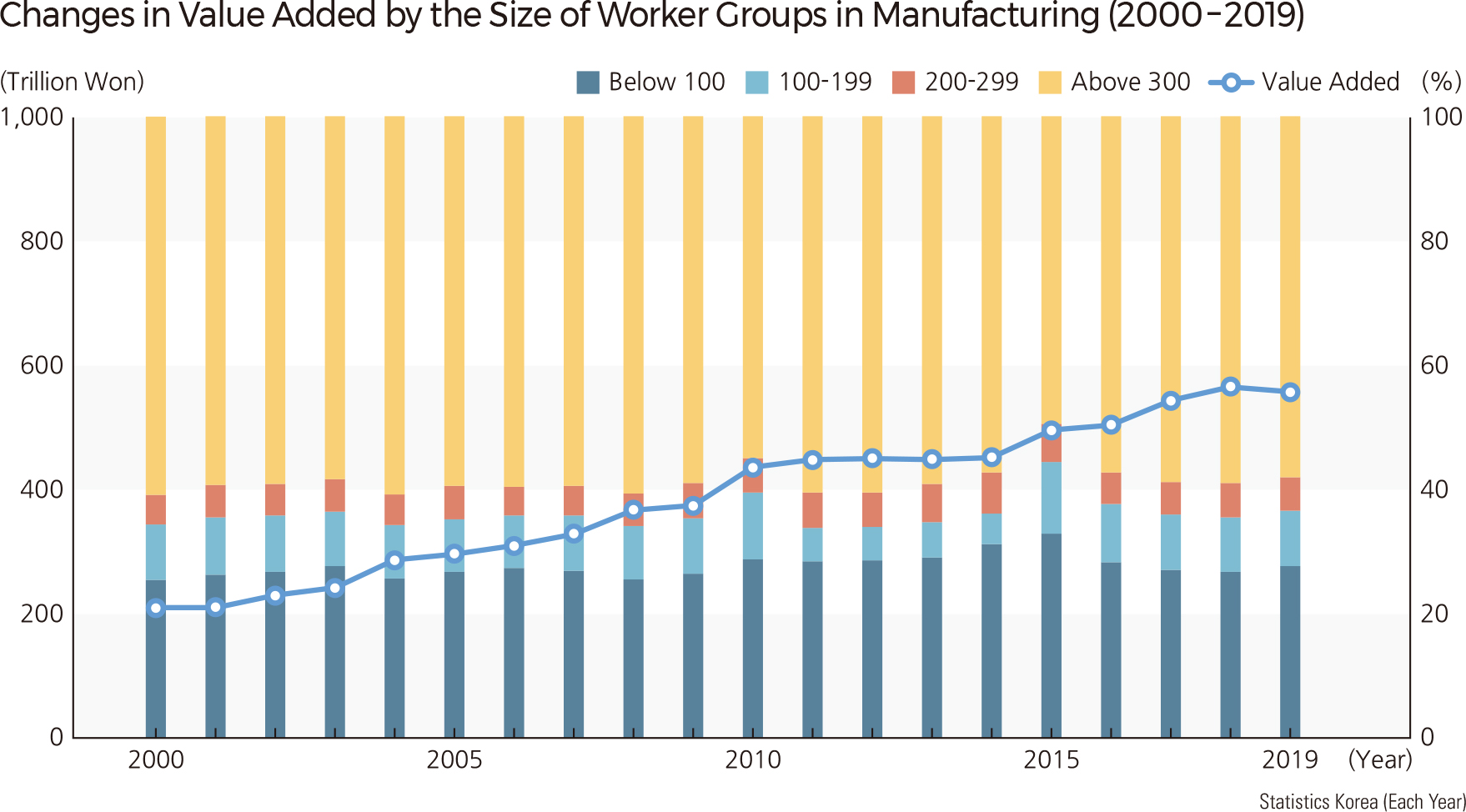

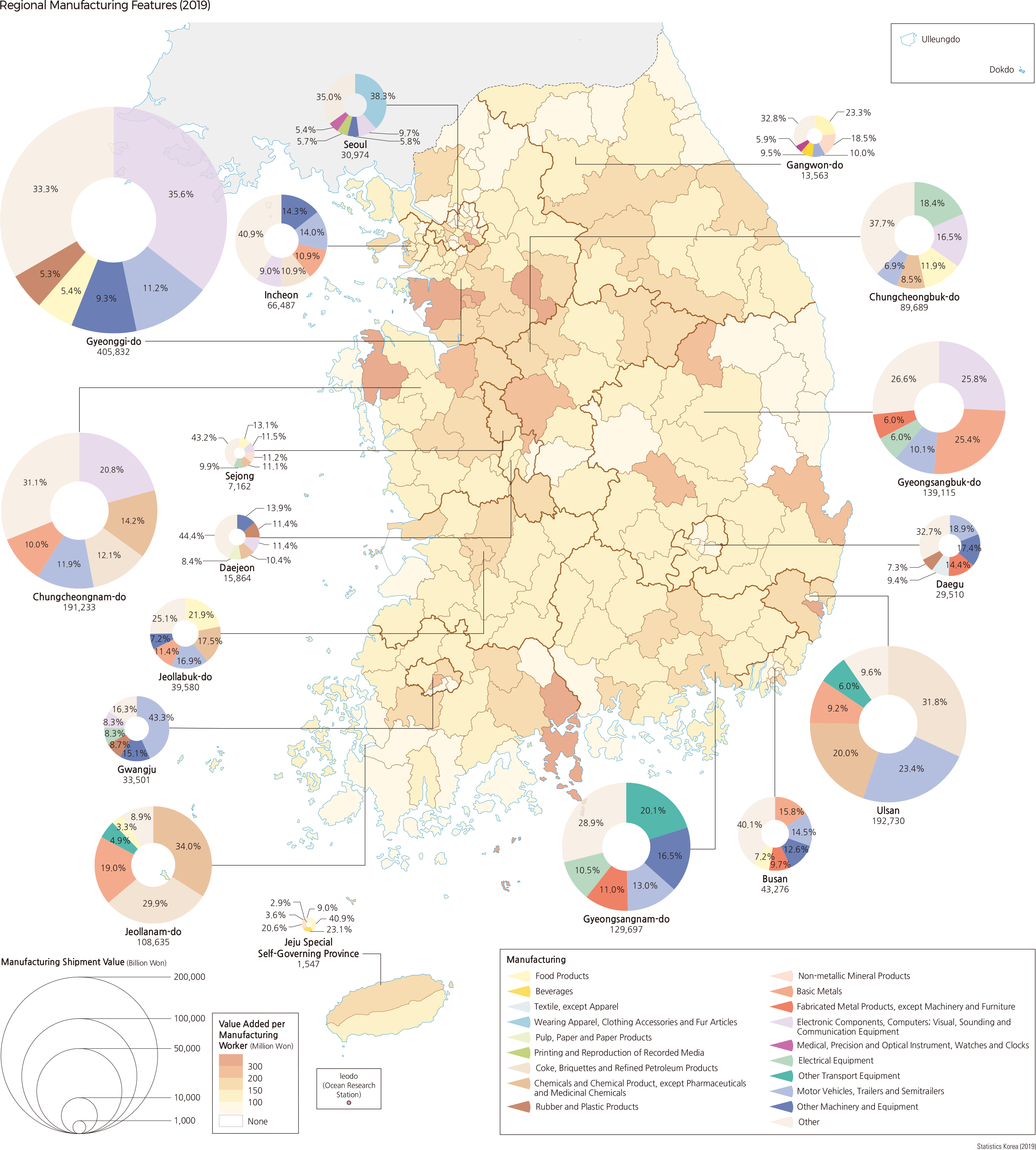

Manufacturing in Korea has gone through tremendous continuous growth during the last 60 years, playing a pivotal role in the nation’s economic development and upgrading the overall industrial foundation. In the early period of industrialization during the 1960s and the early 1970s, the government chose to promote and nurture light industries such as textiles, clothing, wigs, and shoes. However, since the mid-1970s, the government’s industry promotion has shifted to the heavy and chemical industries that served the relatively large domestic markets and provided the foundation for industrialization to take off. In the 1990s, there was a shift in investment emphasis to high-tech industries. Significant high-tech growth, including the development of semiconductors, computers, and information and communication technology, was accompanied by advanced technology training. Since the mid-2000s, stagnated growth in the manufacturing sector has brought a need for a different development strategy. Especially concerning growing fears of the downturn of manufacturing which arose from soaring inflation, global supply chain bottlenecks, and a resurgent COVID-19, it is necessary to implement new measures that can enhance the competitiveness in manufacturing. The nominal value added in manufacturing which was only 490 billion won in 1970, sharply increased to about 485 trillion won in 2019. Likewise, the proportion of added value in manufacturing to the added value of all industries has increased by 8.5% from 19.0% in 1970 to 27.5% in 2019. The manufacturing shipment values by region in 2019 were the highest in Gyeonggi-do (406 trillion won), followed by Ulsan (193 trillion won), Chungcheongnam-do (191 trillion won), and Gyeongsangbuk-do (139 trillion won). The manufacturing shipment values per worker in 2019 were the highest in Jeollanam-do (1.2 billion won/person), followed by Ulsan (1.1 billion won/person), Chungcheongnam-do (760 million won/person), and Gyeongsangbuk-do (580 million won/person). The number of workers in manufacturing increased from about 1.27 million people in 1970 to about 5.16 million people in 1991, the highest since 1970. Since then, the number has mainly turned downward. In 2020, the number of workers in manufacturing fell to 4.38 million people. Likewise, the percentage of the number of workers in manufacturing increased until 1991, after that, it has shown generally downward trends. According to the changes in value added by the size of worker groups in manufacturing from 2000-2019, the share of gross value added of enterprise with over 300 workers was more than 50% annually. Considering the value added in manufacturing increased from about 210 trillion won to about 557 trillion won during the same period, the gross value added of enterprises with over 300 workers increased quite dramatically. The maps of the top five regional manufacturing based on shipment values and the manufacturing’s value added per worker indicate the current regional manufacturing features in Korea. Above all, the manufacturing’s value added per workers in 2019 was the highest in Yeosu-si (930 million won), followed by Nam-gu in Ulsan (640 million won), Seosan-si (610 million won), Hwaseong-si (420 million won), Gwangyang-si (400 million won), Icheon-si (390 million won), Gangnam-gu in Seoul (360 million won), Seo-gu in Gwangju (330 million won), and Asan-si (320 million won). According to the regional representative manufacturing based on shipment values in 2019, the top manufacturing share in each region was as follows: manufacture of wearing apparel, clothing accessories and fur articles (38.3%) in Seoul, manufacture of basic metals (15.8%) in Busan, manufacture of motor vehicles, trailers and semitrailers (18.9%) in Daegu, manufacture of other machinery and equipment (14.3%) in Incheon, manufacture of motor vehicles, trailers and semitrailers (43.3%) in Gwangju, manufacture of other machinery and equipment (13.9%) in Daejeon, manufacture of coke, briquettes and refined petroleum products (31.8%) in Ulsan, manufacture of food products (13.1%) in Sejong, manufacture of electronic components, computer; visual, sounding and communication equipment (35.6%) in Gyeonggi-do, manufacture of food products (23.3%) in Gangwon-do, manufacture of electrical equipment (18.4%) in Chungcheongbuk-do, manufacture of electronic components, computer; visual, sounding and communication equipment (20.8%) in Chungcheongnam-do, manufacture of food products (21.9%) in Jeollabuk-do, manufacture of chemicals and chemical products; except pharmaceuticals and medicinal chemicals (34.0%) in Jeollanam-do, manufacture of electronic components, computer, and visual, sounding and communication equipment (25.8%) in Gyeongsangbuk-do, manufacture of other transport equipment (20.1%) in Gyeongsangnam-do, and manufacture of food products (40.9%) in Jeju-do. The current major manufacturing industries in Korea have served as the foundation of national economic growth for years. The top five new emerging industries will become the future cornerstone of Korea’s economy. The current major manufacturing in Korea are as follows: (1) the machinery group including manufacture of motor vehicles, shipbuilding industry, and general purpose machinery manufacturing, (2) the materials group including the steel industry, oil refining, and chemical industry, and (3) the ICT group including household electric appliances industry, communication and broadcasting apparatuses, and semiconductor manufacturing. The top five new emerging industries are as follows: (1) next generation semiconductor industry, (2) new metal material industry, (3) next generation ceramic material industry, (4) advanced chemical material industry, and (5) high-tech textile material industry. |